The Reupholstery of Van Treight Chairs

The Story of Van Freight Furniture

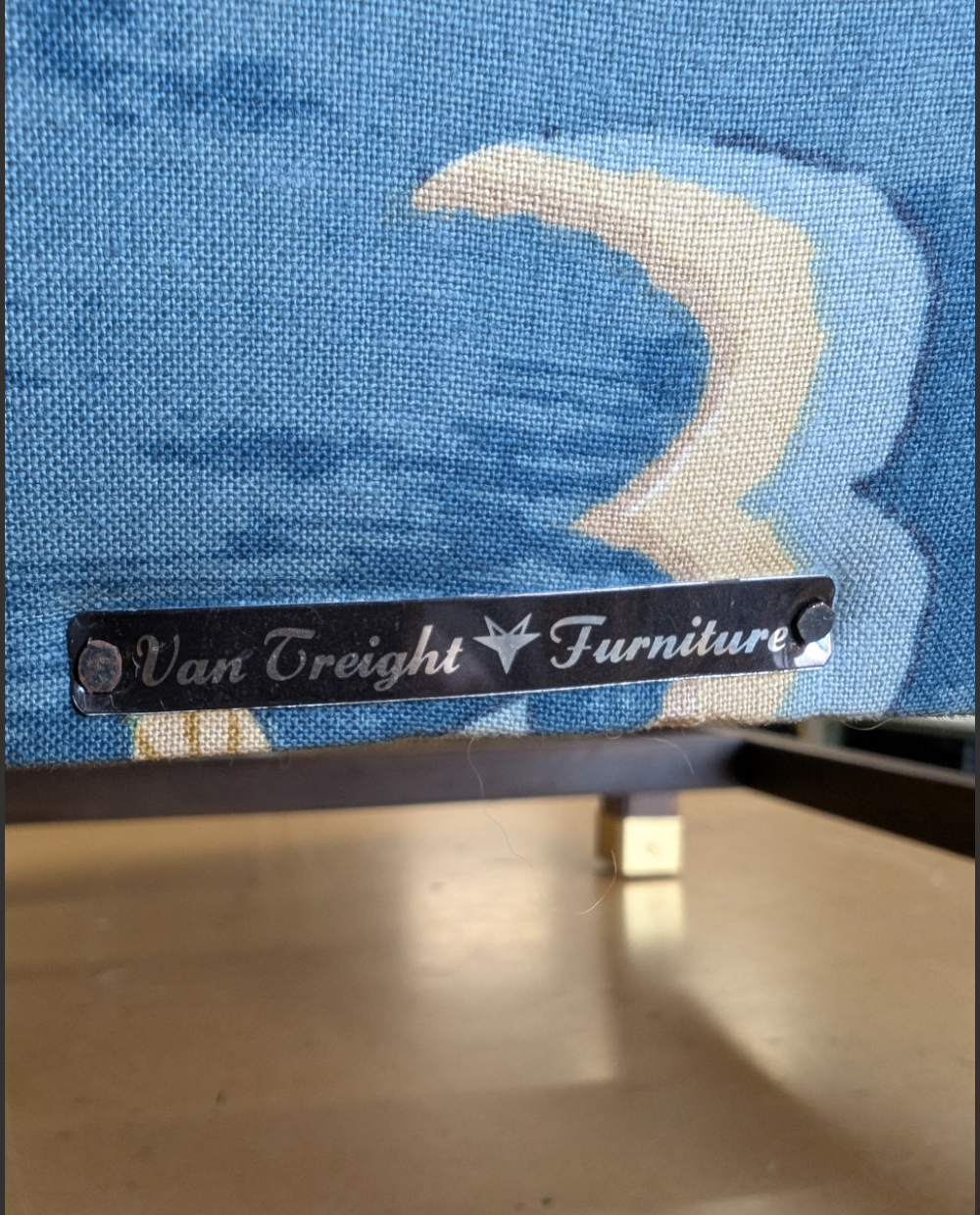

Van Treight Furniture was founded by John Van Treight in 1947. Operations commenced with only one assistant, making nursery furniture from a shed in Parramatta. The business grew rapidly moving into manufacturing quality colonial style bedroom, dining and lounge furniture. In 1959 they made the shift into their Homebush factory with about 50 staff. In the early 1960’s the company also started producing Scandinavian influenced design. Then in 1966 acquired the rights to import and manufacture under licence from Drexel Heritage. In 1972 Van Treight shifted to a new purpose-built factory at North Rocks NSW employing about 65 staff. By the mid 1980’s they were employing over 130 staff and supplying top-end furniture to the leading national department stores and specialist furniture retailers.

Flash forward twenty years and the renowned furniture manufacturers were toppling due to cheap imitation furniture flooding in from Asia. Van Treight Furniture officially closed in 2001 and Drexel Heritage filed for bankruptcy in 2014.

Our Clients Story

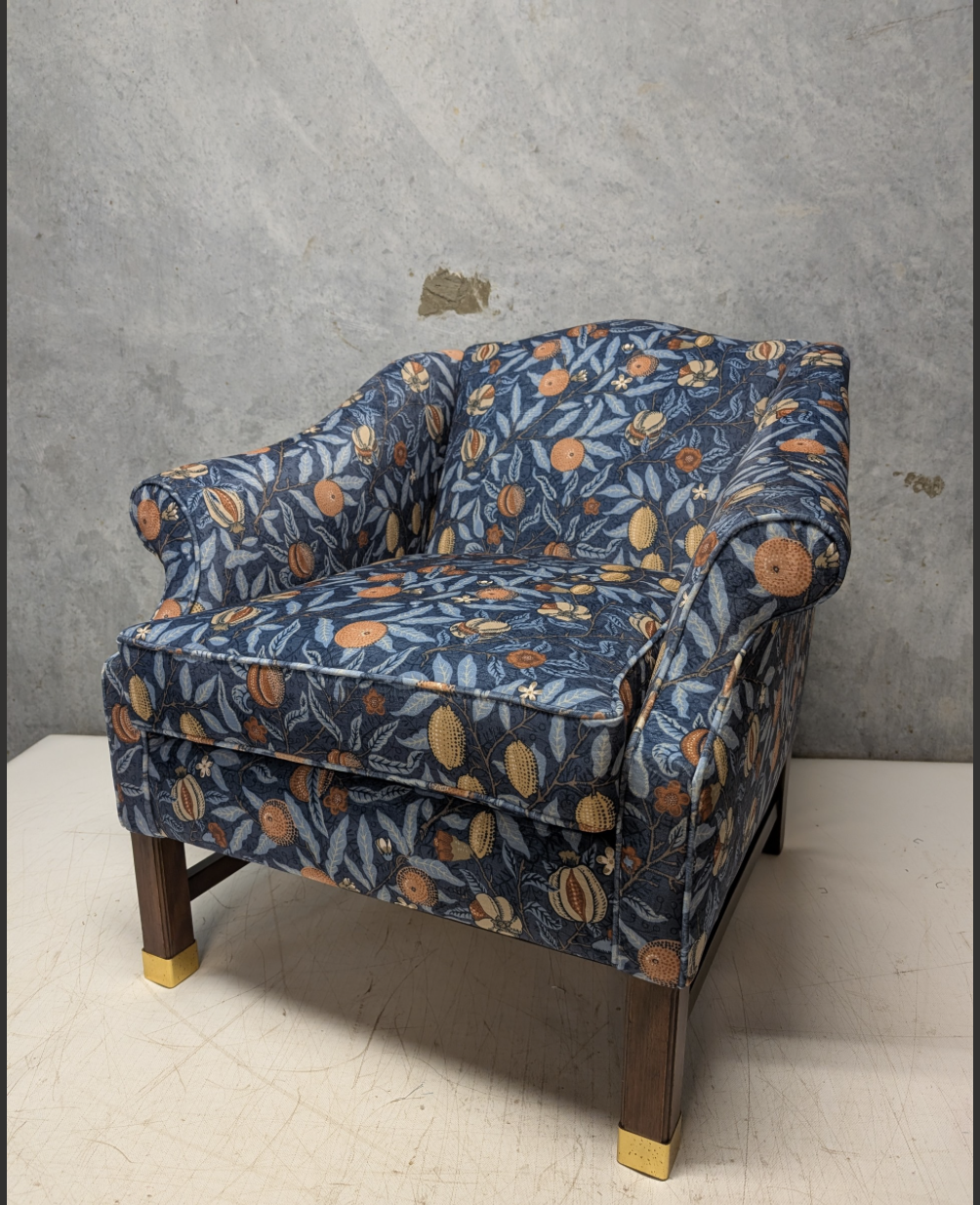

Our Fremantle based client contacted us saying she had two chairs which she purchased in 1978 for her husband’s home study. The chairs were in severe need of refurbishment. Upon inspection of these chairs, we instantly recognised them as Van Treight, one of the legendary local manufacturers from the golden age of Australian furniture manufacturing.

How We Transformed the Chairs

Reupholstering the Chairs

- We completely removed all the existing upholstery from the chairs revealing a timber frame.

- The timber show-wood bases were cleaned then touched up with stain and polish.

- The original seats and back zig-zag springs were still in good condition so we just fitted additional spring edge wire links.

- The upholstery fabric was selected, it was the William Morris ‘Fruit Velvet – Midnight’ which suited the chair design.

- Cutting patterns were developed with the fabric being carefully pattern matched.

- High density foam was fabricated and laminated to the frames.

- The bodywork was then upholstered bringing the chairs slowly back to life.

- The outside arm and back panels were lined and padded then carefully upholstered with piped detail.

- The back cushioning was fabricated using polyester filled channelled and quilted inserts and the seat cushions were fabricated from premium foam encased with bonded polyester fibre. When filled the cushioning completed the rejuvenation.

The End Result

Behind every re-upholstery job is a story and when the chairs were delivered the warm smile on our client’s face said it all.